Learning How to Assemble

If this is your first build, take a moment to understand the manual structure and the components you’ll be using.

Manual Structure & Timing

The manual is divided into logical sections. Here is an approximate time for each:

| Section | Description | Approx. Time |

|---|---|---|

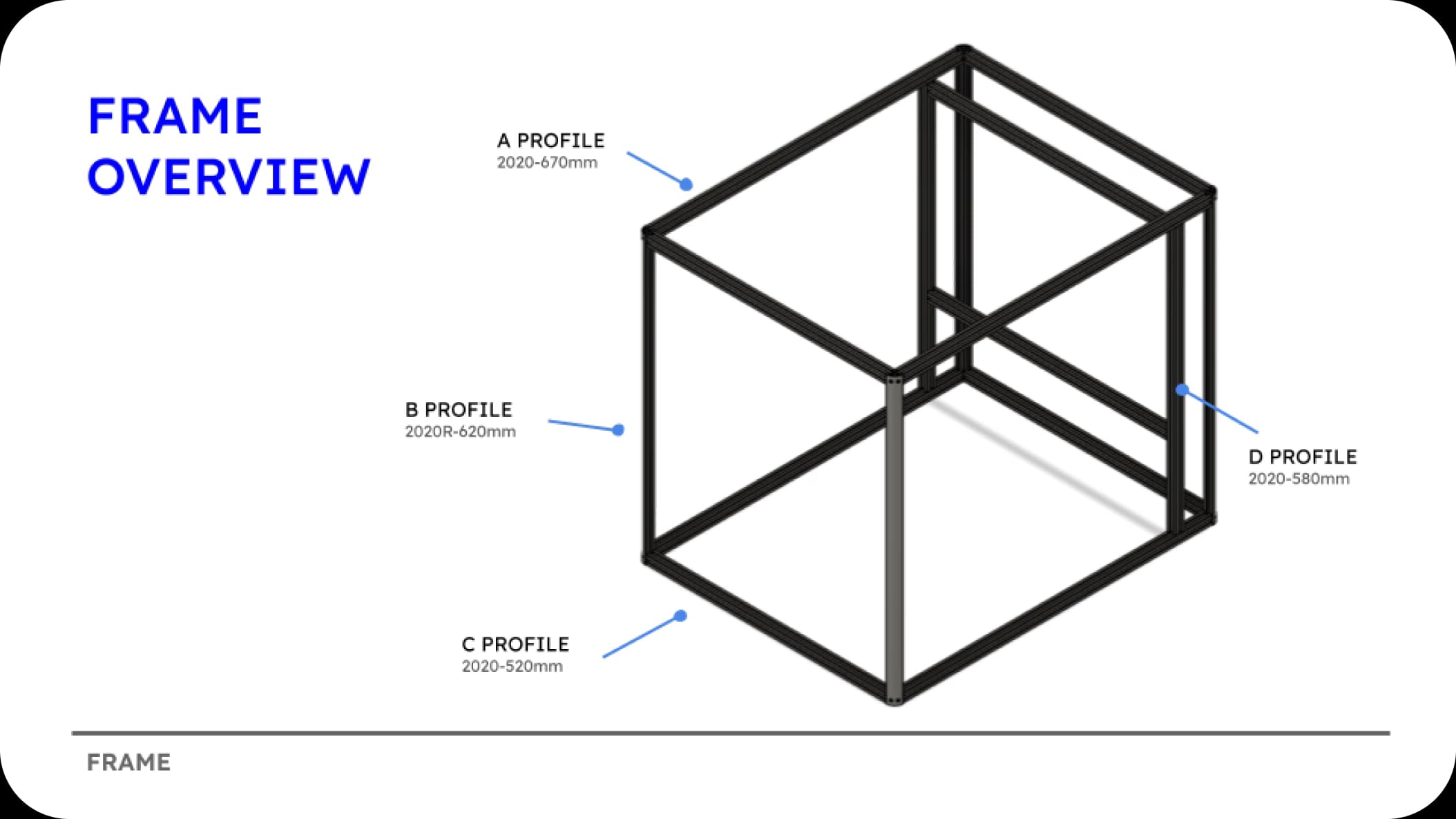

| Frame Assembly | Building the aluminum skeleton | 45-60 mins |

| Panel Installation | Installing acrylic panels | 30-45 mins |

| Electronics | Mounting PSU, wiring, screen | 60-90 mins |

| Final Checks | Calibration and testing | 20 mins |

How the Manual is Structured

The assembly process is divided into logical sections, each following a standard format:

Introduction & Overview

Each section begins with a general introduction followed by an overview of the sub-assembly you will be building.

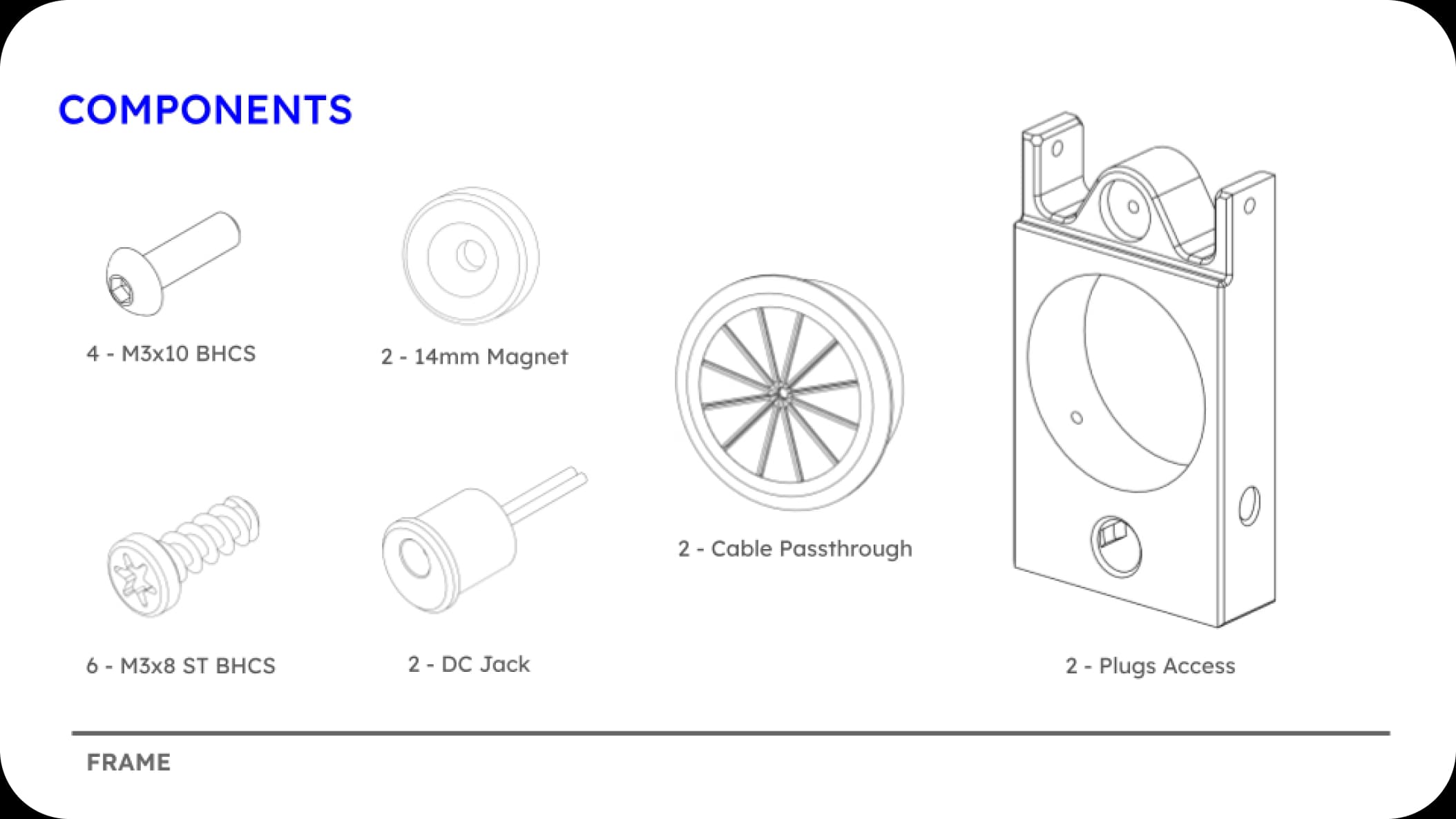

Component Preparation

Before you start building, the manual lists all the specific components and hardware needed for that section.

Section Completion

Every section ends with a clear visual separator to indicate the transition to the next part of the build.

Essential skills

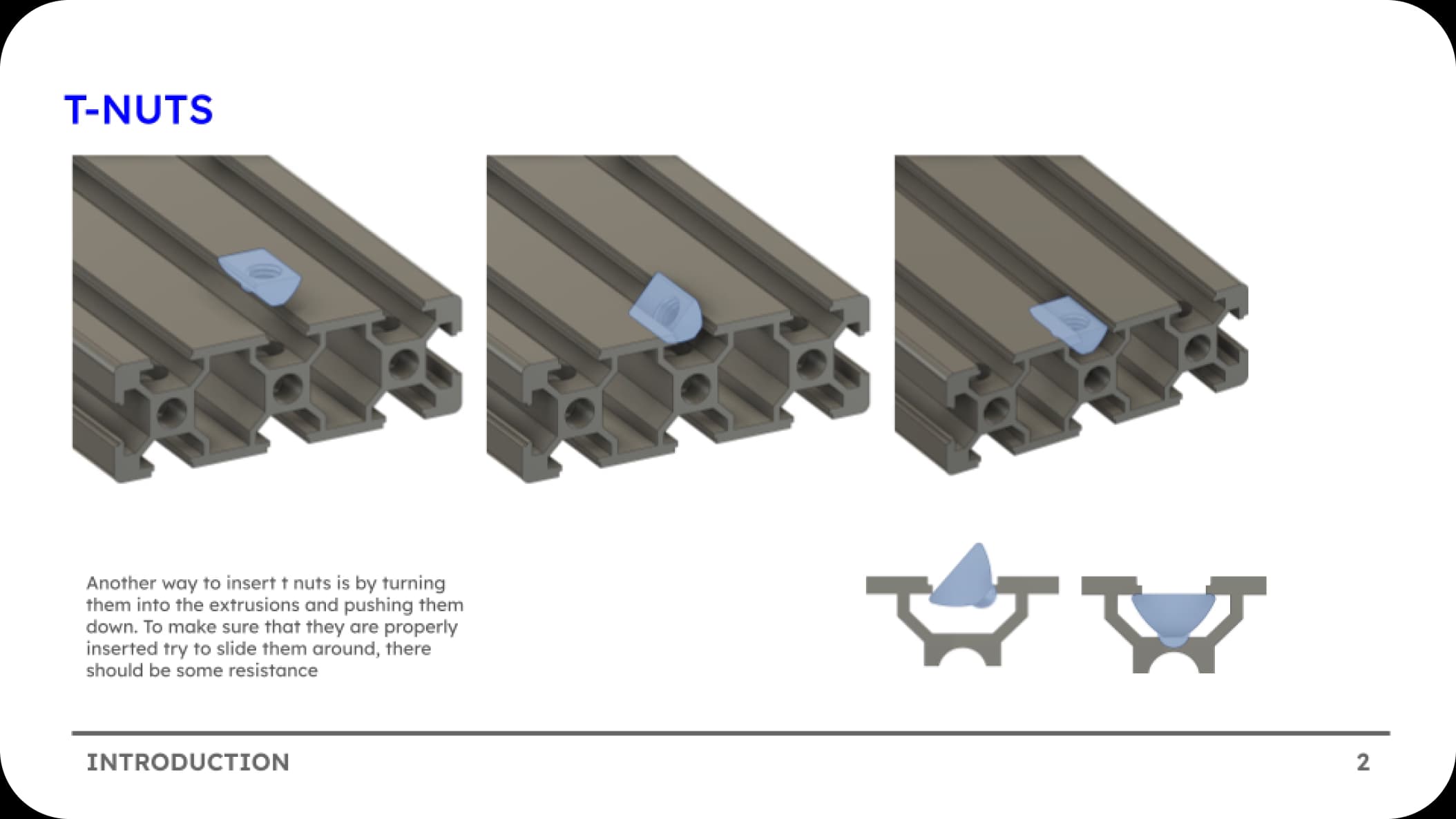

T-Nuts

Pretty much discontinued from the assembly process because of the simplicity of hammerhead nuts, but might be useful in a couple of steps.

- Installation: Insert into slot

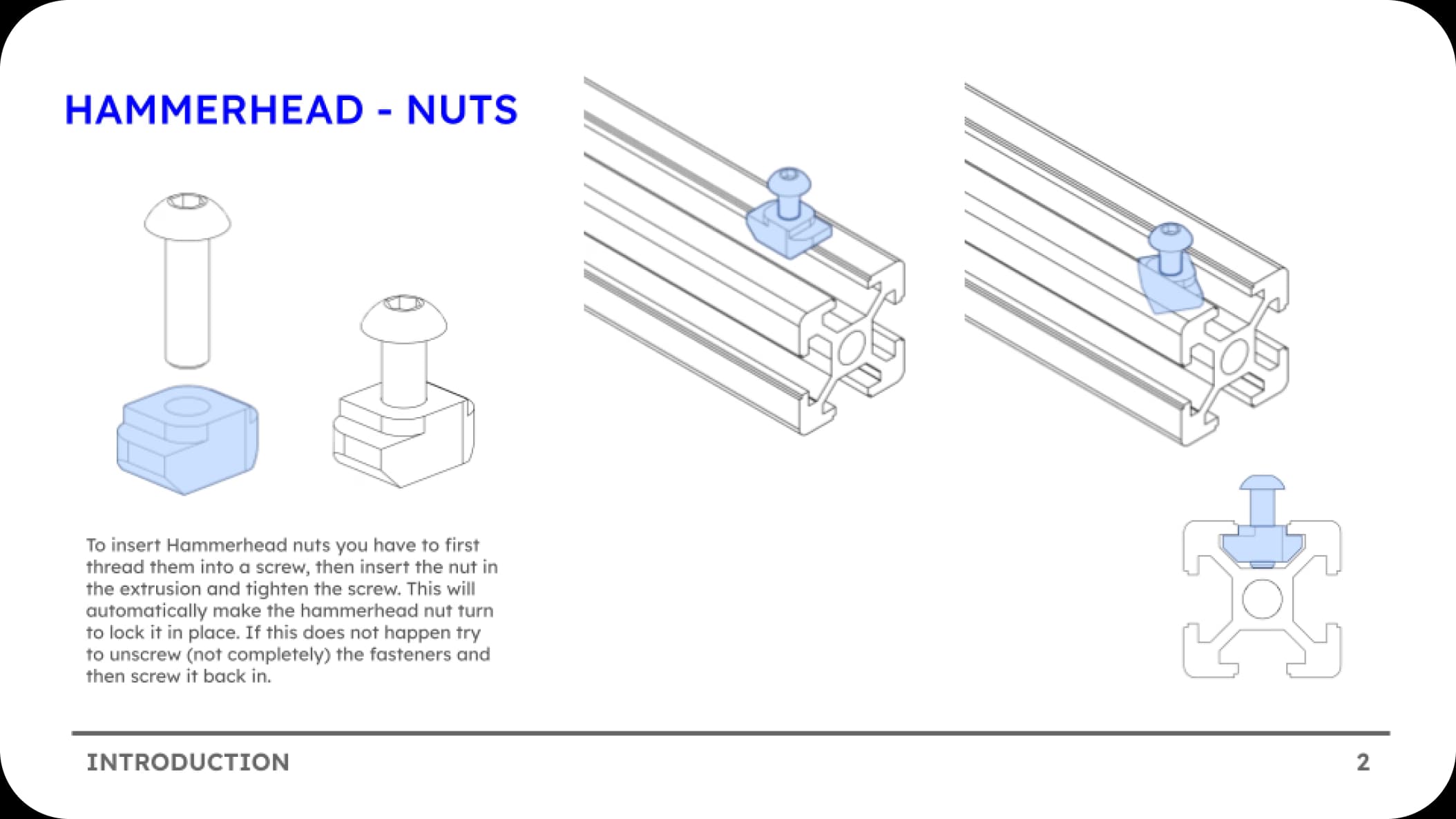

Hammerhead Nuts

Similar to T-Nuts but designed for insertion directly into extrusions with the part. (no need to pre place them).

- Installation: Insert into slot and then they will turn 90 degrees to lock.

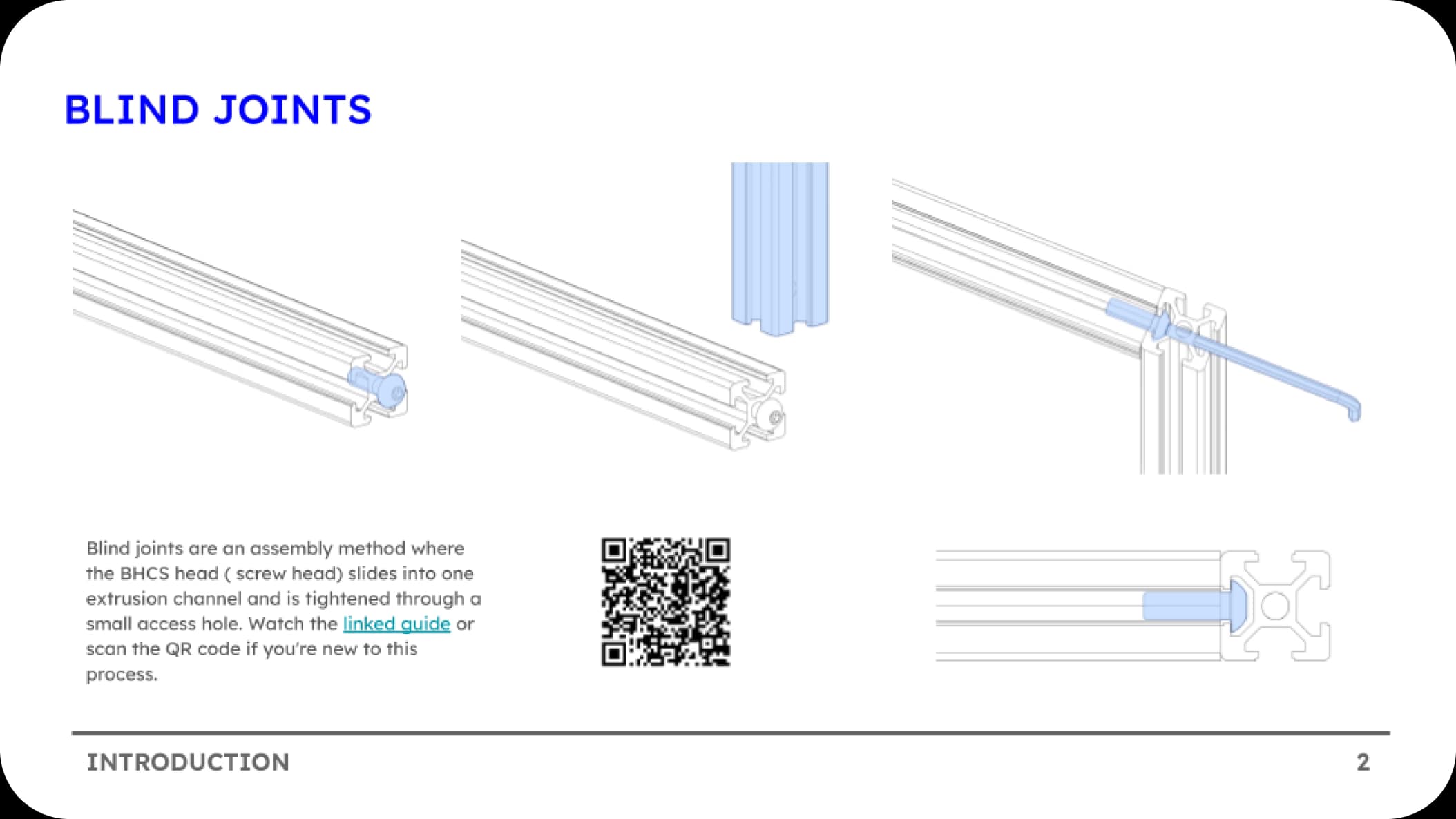

Blind Joints

This is the primary method used to assemble the frame, providing a clean and hidden connection between extrusions.

If you are new to blind joints, we highly recommend watching this demonstration by Canuck Creator: Watch Video